- We Provide After Sales Support 24x7 365 days. Our Engineers can visit any site in shortest possible time

- +91 130 2216666

- manish@jaschgauging.com

Plastics – Global Trendsetting Technology

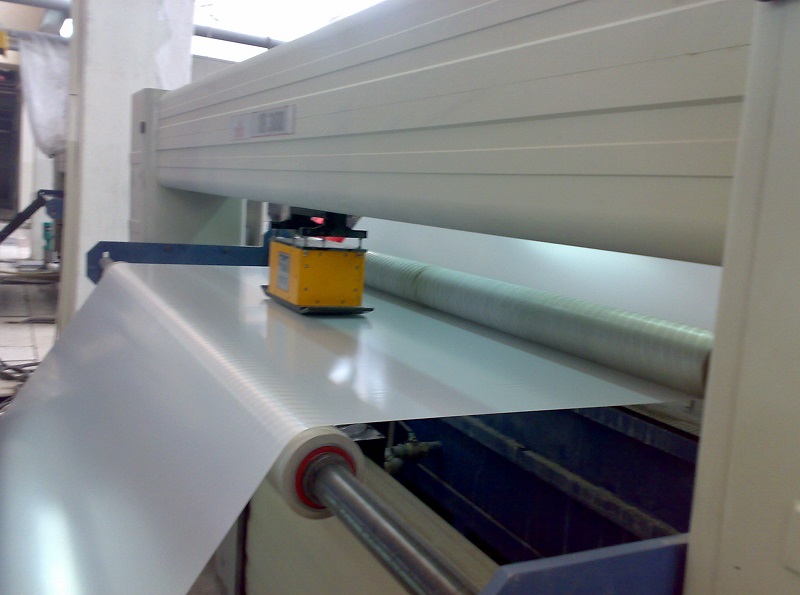

Plastic Thickness Gauge BTG 3000

Jasch has provided leading measurement innovation for over 45 years in the Plastics market. Whether the process is film extrusion, sheet, co-extrusion, blown film, cast, bi-axial or a range of other process methods, Jasch has a solution for you.

The range of Jasch products and services set a new standard in terms of quality assurance and process optimization. Our explicit objective is to ensure the best possible value no matter how diverse the individual requirements are.

Jasch specializes in helping to ensure the consistent, uncompromising quality and ROI of all products produced in a web process form; Plastics, Non-wovens, Coating/Converting, Extrusion, Paper/Board/Tissue, Calendering, Metals and Carpet.

Why do so many industry leaders worldwide rely on Jasch’s high performance systems to optimize their process and reduce cost to manufacture?

Jasch has been a dependable Gauging Supplier for over 45 years and many of our customers have systems still operating over 30 years later. Jasch provides an effective upgrade path to keep your system operating with the latest EnvisionUltra, Controls and Sensor technologies.

Industry Processes Include:

- Sheet Extrusion

- Film Coating

- Laminations

- Cast Film

- Cellophane Film

- Blown Film

- Foam Extrusion

- Co-Extrusion

Providing Measurement and Control Technology for:

- Thickness (Non-Contacting)

- Density

- Basis Weight

- Co-Extrusion

- Layer Discrimination

- Cascade MD Control

- Roll Control

- APC Control

- SPOT-Track (Same spot control)

- Vision Surface Inspection

- Color Interpretation

- Data History

- Process Analysis

- Remote Connectability

- Open Architecture

Features

- Non-contact measurement

- Large size color TFT display suitable for harsh industrial environment

- High speed scanning up to 250 mm per Second

- Air gap temperature compensation for measurement on hot webs

- Automatic calibration after predefined interval for measurement stability

- Automatic edge-detection of the web for accurate profile mapping

- Touch Screen Controls for ease of use

- Highly precise (optionally pressurized) O-frame free from deflection and misalignment

- Comprehensive Production Reports

Design and Construction

The sensor is designed on a large volume pressurized ionization chamber coupled with a highly stable electrometer amplifier. The scanner is built on rugged steel structure free from deflection and misalignment to ensure precise sensor positioning. All linear motion system components are CNC machined to precise alignment for long service life. The frame is an enclosed construction to shield all mechanical and electronic components from ingress of dust and corrosion. The scanner is linked with the operator station through a high speed serial link. The operator station has a PC (Personal Computer) architecture with industry-standard hardware and software which allows for easy upgrades and local support throughout the world. The operation is through touch screen for easy and efficient operator interaction. The standard displays provided are cross-web, machine direction profiles, trends, product recipe and roll reports. SPC charts are available as an option.

Controls Options

- Machine Direction control through Line speed / Extruder screw speed control

- Cross Direction control through

- Die Bolt heating control

- Roll Bending control

- Cross Axis control.

- Roll Gap control

- Coating Knife/ Blade control

- Radioactive Source : Krypton 85, 200mCi

- Accuracy & Repeatability : ±25% or 0.25 GSM (the greater)

- Measurement Range : 0-1200 GSM (g / m2).

- Air Gap : up to 15 mm

- Operating Temp. : 0-50 degree Celsius.

- Sampling Time : 10msec

- Radioactive Source : Strontium 90, 50mCi

- Accuracy & Repeatability : ±25% or 0.5 GSM (the greater)

- Measurement Range : 0-5000 GSM (g / m2).

- Air Gap : up to 25 mm

- Operating Temp. : 0-50 degree Celsius.

- Sampling Time : 10msec

- Source : X-Ray (Selectable energy and power as per application)

- Accuracy & Repeatability : ±1% or 0.1 GSM (the greater)

- Measurement Range : 0-10000 GSM (g / m2).

- Air Gap : up to 25mm

- Operating Temp. : 0-50 degree Celsius.

- Sampling Time : 10msec